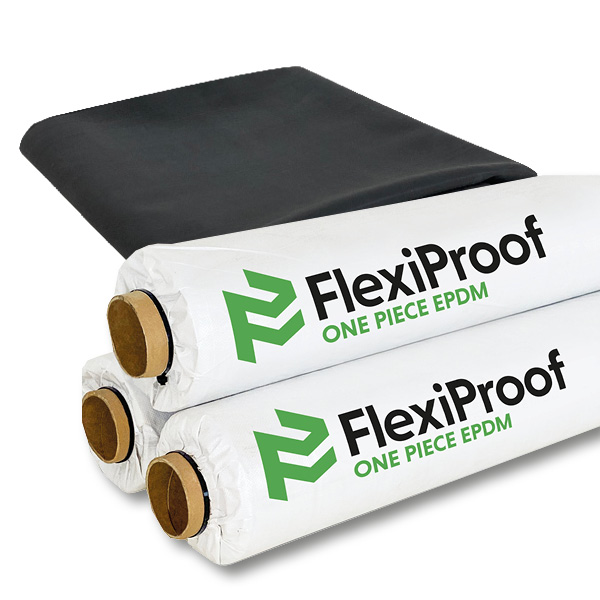

One Piece EPDM Membranes

The durable and dependable, easy-install, flat-roof system.

From garages and garden rooms to extensions and large construction projects, FlexiProof One Piece EPDM membranes beautifully finish and protect flat roofs of all sizes.

![]()

SMART

AESTHETICS

![]()

TECHNICAL

SUPPORT

![]()

TRAINED

INSTALLER

NETWORK

![]()

TOTALLY

WEATHERPROOF

FULLY

RECYCLABLE

![]()

ISO 9001

REGISTERED

PRODUCTION

One Piece EPDM Membranes

“Produced with state of the art extruded EPDM technology for long term flat roof success – wind, rain or shine.”

The strong and durable flat roof system – long term

FlexiProof One Piece EPDM membranes are designed and manufactured for long-term flat roof success.

Produced in an ISO 9001 registered facility and using state of the art extruded EPDM technology, FlexiProof One Piece EPDM membranes deliver where (and when!) it counts.

Fully accredited

Puncture resistant and strong enough to walk on, with elasticity to easily handle building movement, FlexiProof One Piece EPDM membranes are also CE-marked and Broof (t4) fire rated for ultimate integrity and peace of mind.

50 year life expectancy and 25 year membrane warranty

FlexiProof One Piece EPDM membranes won’t peel, crack or split.

They’re the smart choice for long term, great looking building protection.

Weighing much less than bitumen felt and provided in homogenous one piece sheets at two thicknesses, FlexiProof One Piece EPDM membranes are easy to handle and apply to flat roofs of all sizes.

Mitigate health and safety risks

Quickly and easily cold-applied, FlexiProof One Piece EPDM membranes enable installers to avoid the health and safety risks associated with flame-applied bitumen felt roofing materials.

Bespoke membrane sizes

Thanks to a range of EPDM membrane sizes, CAD- designed edge trims and components and specially formulated adhesives, the complete FlexiProof One Piece EPDM flat roof system enables fast and safe installations – every time.

The state of the art EPDM flat roof system.

Lightweight, safe and easy to install

Call us for advice or a quote:

01306 400801

Premium Materials &

Technology

- Homogeneous one piece EPDM sheets – high strength and smooth finish, even at longer lengths

- Extra wide EPDM sheets are created ahead of the curing process while the rubber is still tacky and being formed.

- Puncture resistant and strong enough to walk on

- Integra Trim – full range of CAD designed edge trims and components for a perfect fit

- Manufactured in an ISO 9001 registered facility

- Fully recyclable

Fast & Safe

Installation

- Cold applied, flame-free installation

- Available in a variety of roll widths to minimise waste on every roofing project

- Available in three thicknesses -our standard 1.14mm, our premium 1.20mm and our heavy duty 1.52mm – to help meet all project requirements and budgets

- Weighs much less than bitumen-

based roofing materials - Specially formulated adhesives for fast application and exceptional bonding strength

- Integra Trim corner and joiner components quickly and easily glued into place

Long Term

Success

- CE-marked and manufactured in ISO900125-registered facility

- A lifetime of elasticity – independently tested 340% EPDM elongation allows for all building movement – and will not degrade over time

- 50 year life expectancy

- 25 year membrane warranties available upon request*

- Insurance-backed warranties also available

- Broof (t4) fire rating

*For certified installers only.

![]()

BROOF T4

FIRE RATING

![]()

CE

CERTIFIED

![]()

50 YEAR LIFE EXPECTANCY

![]()

25 YEAR MEMBRANE

WARRANTIES

Cut to size one piece sheets

Utilising state of the art EPDM extrusion technology for high specification strength and elasticity, FlexiProof One Piece EPDM membranes deliver great looking, long term building protection.

- Available in widths of 3.05m, 4.58m and 6.10m

- Each width can be ordered at any length to a maximum of 30.50m

- Available in three thicknesses – our standard 1.14mm, our premium 1.20mm and our heavy duty 1.52mm – to suit all applications and budgets

Product Guides

FlexiProof One Piece

Product Guide

Product and Installation Guides

FlexiProof One Piece

Product Guide

Installing the Membrane

Install Guide

Seaming Sheets Together

Install Guide

Using Termination Bars

Install Guide

Joining to Lead Flashing

Install Guide

Butt Joining

Install Guide

Internal Corner Detailing

Install Guide

Fleece Backed EPDM

Need advice or a quote?

Contact us today - we're here to help you succeed.