Calendering Vs. Extrusion:

A Detailed Look at EPDM Flat Roof Membrane Manufacturing

EPDM (Ethylene Propylene Diene Monomer) membranes have become a cornerstone in flat roofing due to their resilience, flexibility, and longevity.

Introduced in the late 1960s in the USA, EPDM has seen increasing use in commercial and residential roofing. However, the quality of EPDM membranes is determined by the manufacturing method used – primarily either calendering or extrusion – and understanding these methods is critical when selecting EPDM membranes for long-term durability, performance, and aesthetic finish.

This article addresses:

• How are calendering and extrusion used to manufacture EPDM membranes?

• What are the advantages and disadvantages of each method?

• How do these processes affect the performance of EPDM in roofing applications?

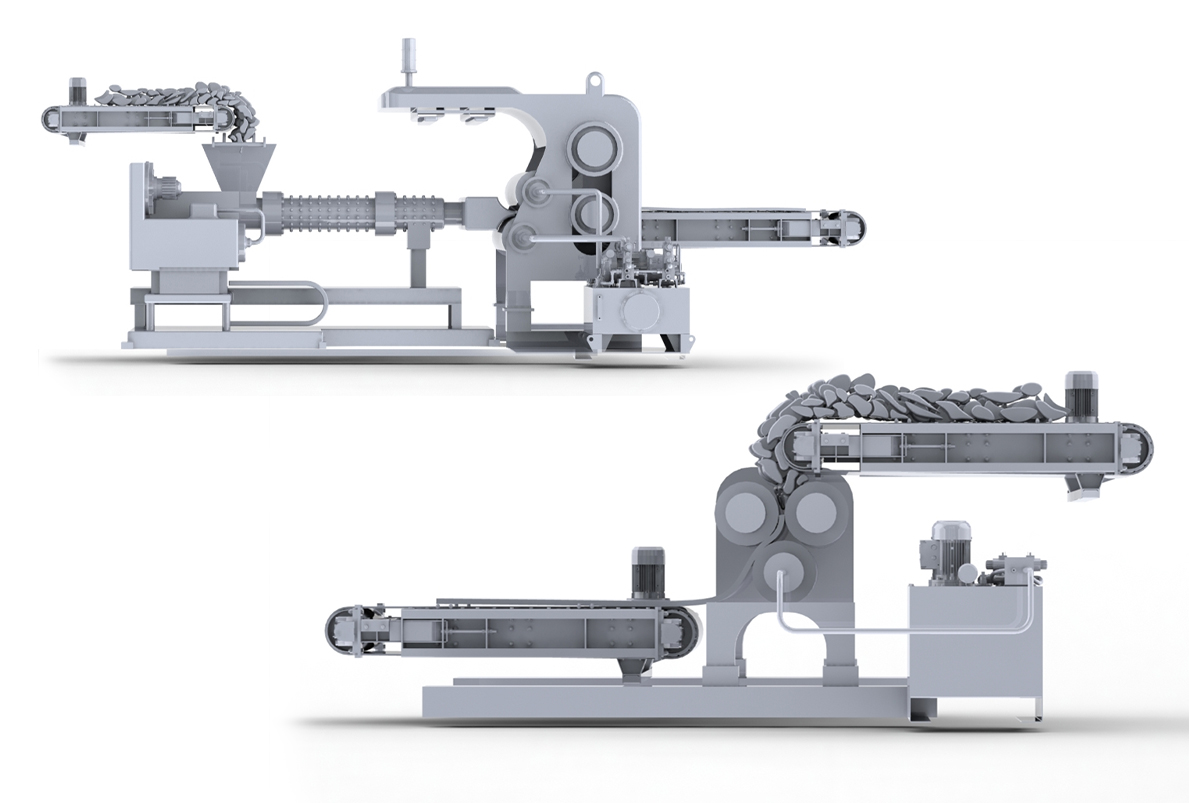

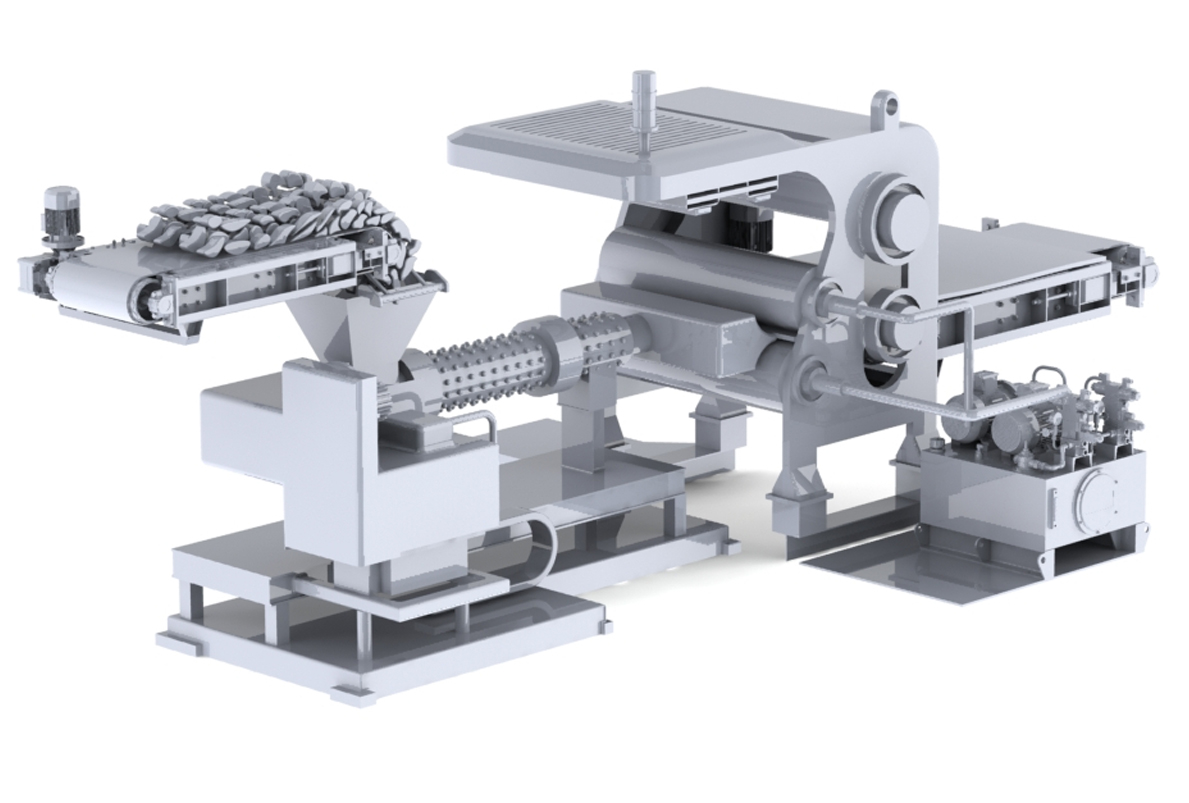

The Calendering Process

Calendering has been a key technique in the rubber industry for decades and remains a common method for producing EPDM roofing membranes. Rubber polymers are blended and softened by heating, then passed through a series of rollers, forming a flat sheet. The sheet’s thickness is controlled by adjusting the distance between the rollers and, after the desired thickness is achieved, the sheet is rolled, cured, and prepared for installation.

Strengths of Calendering

The calendering process is relatively straightforward and has been refined over decades of use. When the process runs smoothly, it’s particularly well-suited for producing uniform sheets of a specific size. In the past, the roofing industry has heavily relied on calendering because of its ability to mass-produce sheets of EPDM for large-scale projects.

Weaknesses of Calendering

Despite advances in calendering equipment, there are inherent drawbacks to the process:

Inconsistencies in Thickness

One of the major issues with calendering is the difficulty in maintaining consistent thicknesses, especially when producing very thin or very thick sheets. As the thickness increases, the likelihood of air entrapment within the sheet rises, leading to potential weak points or bubbles. For thinner sheets, pinholes and voids may develop, compromising the membrane’s ability to provide complete protection.

Air Pockets and

Dimples

Rolling banks of rubber and warm-up mills are used in calendering to maintain the material flow, but these systems can introduce air pockets or other inconsistencies into the final sheet. These defects can weaken the membrane and lead to future issues like leaks or accelerated aging.

Scorching and Premature Curing

Another concern is the risk of overheating the rubber, which can cause localised scorching or pre-curing of the membrane. This occurs when the material experiences uneven temperature cycles, particularly in the larger rolling material banks.

The Extrusion Process:

A Modern Solution

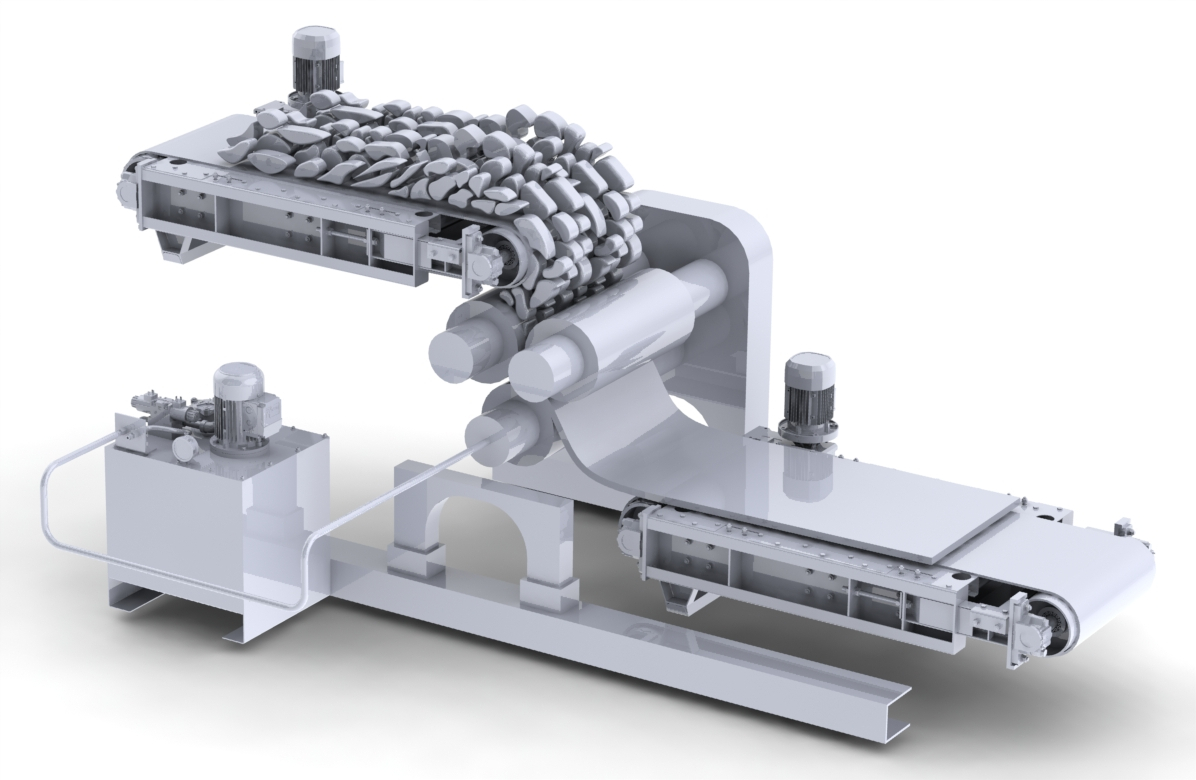

In response to the limitations of calendering, the extrusion process has been developed and is now widely regarded as a more advanced method for manufacturing EPDM membranes. Extrusion involves feeding rubber material (either in pellets or slabs) into a machine that heats, blends, and shapes it into a continuous sheet with precise control over the thickness and composition.

Strengths of Extrusion

Extrusion offers several significant advantages over calendering, due to the precision and control it provides throughout the manufacturing process:

Uniform Thickness

By using extrusion, manufacturers can produce EPDM membranes with a far more consistent thickness across the entire sheet. This is achieved by regulating the speed of the extruder screw and using temperature control along the length of the extrusion barrel. This level of precision helps avoid the issues with pinholes and air bubbles common in calendered sheets.

Temperature Regulation

Extrusion also allows for more refined temperature management. Multiple zones of temperature control in the extruder ensure that the rubber remains at an optimal temperature throughout the process. This prevents premature curing or scorching, producing a membrane that is consistent in quality from end to end.

Elimination of Air Pockets and Defects

The extrusion process avoids the need for rolling material banks, a feature of calendering that often introduces air pockets and defects. With controlled rubber flow, and the advanced design of extrusion dies, the risks of dimples and air pockets are minimised, leading to a smoother and more reliable membrane.

Fewer Surface Defects

Since the extrusion process consistently controls the blending and heating of the material, the resulting membrane has fewer surface defects such as dimples and entrapped air. The smoothness of the extruded EPDM membrane contributes to its overall durability and ease of installation.

Detailed Comparison: Calendering Vs. Extrusion

Thickness

Consistency

Calendering:

Maintaining a uniform thickness can be a challenge in calendering, particularly for very thin or thick sheets. Thin sheets are prone to pinholes and voids, while thicker sheets may trap air, creating weak spots that reduce the membrane’s durability.

Extrusion:

The extrusion process excels at producing a consistent thickness throughout the sheet, even for extra-wide membranes. Using precise control of the screw speed and die lip design, extrusion allows for real-time adjustments to the sheet’s dimensions, producing a smooth and uniform surface.

Prevention

of Defects

Calendering:

Maintaining a uniform thickness can be a challenge in calendering, particularly for very thin or thick sheets. Thin sheets are prone to pinholes and voids, while thicker sheets may trap air, creating weak spots that reduce the membrane’s durability.

Extrusion:

The extrusion process excels at producing a consistent thickness throughout the sheet, even for extra-wide membranes. Using precise control of the screw speed and die lip design, extrusion allows for real-time adjustments to the sheet’s dimensions, producing a smooth and uniform surface.

Installation and Performance Benefits

Calendering:

Calendering requires rolling banks of material, which increases the likelihood of defects such as dimples, air pockets, or scorching, which can weaken the membrane.

Extrusion:

With extrusion, the rubber is kept in controlled contact with surfaces throughout the process, reducing the possibility of defects. The smoothness of the extruded sheet, combined with its uniform thickness, ensures better performance during installation.

Conclusion: The Future of EPDM Roofing

Choosing extruded EPDM membranes can positively impact the success of a flat roofing project. While calendering remains viable, extrusion has emerged as the superior manufacturing process. By producing membranes with greater uniformity, fewer defects, and enhanced durability, extrusion sets a new standard for high-performance roofing materials.

Merchants and contractors benefit from extruded EPDM’s advantages, particularly when seeking a long-lasting, reliable solution for flat roofing systems and wanting a competitive edge.

As roofing technology continues to evolve, extrusion is likely to become the preferred method for manufacturing EPDM membranes. This method provides a higher-quality product that meets the demands of modern construction. The bottom line is that extruded membranes deliver a higher manufacturing standard and are aesthetically far superior to calendared membranes.

“Extruded EPDM membranes offer clear advantages over calendered ones. Extrusion provides greater consistency, fewer defects, and better durability, making it ideal for longer-lasting, better-looking EPDM flat roofs.

For merchants and contractors, extruded EPDM means a more reliable and competitive solution for flat roof projects.”

Flat roof success for all

Made with the right materials and processes, EPDM is the perfect material for successful flat roof projects.

The EPDM compounds, extrusions and manufacturing processes used to create FlexiProof One Piece and Fleece Backed EPDM membranes are carefully selected and maintained to deliver long-term flat roof success.